- Product Details

Keywords

- silane coupling agent

- 2530-85-0

- A-174 Z-6030 KBM-503 GF31

Quick Details

- ProName: Silane KH-570(A-174)

- CasNo: 2530-85-0

- Molecular Formula: CH2=C(CH3)COO(CH2)3Si(OCH3)3

- Appearance: Clear liquid

- Application: Coatings, Adhesives and Sealants

- DeliveryTime: 5 days

- PackAge: drum or IBC

- Port: Nanjing

- ProductionCapacity: 3000 Metric Ton/Year

- Purity: 98% min

- Storage: In the cool, dry place

- Transportation: by sea

- LimitNum: 5 Metric Ton

Superiority

Features and Benefits

The methacryloxylsilane produced by silane KH-570.

· Significantly improves composite strengths when the composite is reinforced with fibreglass roving sized with a typical polyester-compatible formulation. These formulations normally incorporate silane coupling agents, film-forming resins, lubricants and antistatic agents.

· Enhances the strength performance, both initially and after wet-conditioning, of cured polyester resin composites filled with silica, glass, silicates and many metal oxides.

· Enhances the wet electrical properties of many mineral-filled composites, such as crosslinked polyethylene and polyvinyl chloride.

· May be copolymerized with vinyl acetate and acrylate or methacrylate monomers to prepare silylated polymers that are moisture-curable. These silylated polymer may be used in coatings, adhesives and sealants to provide superior adhesion and durability.

Details

Silane KH-570(A-174)

Introduction

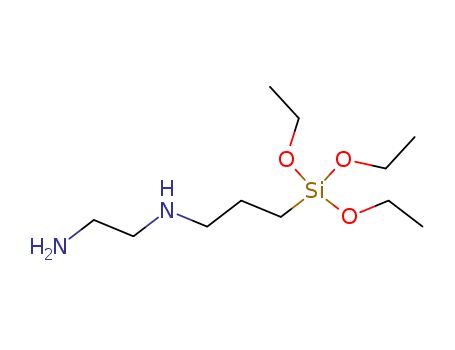

Chemical Name : gamma-methacryloxypropyltrimethoxysilane

CAS NO. : 2530-85-0

Molecular Formula:CH2=C(CH3)COO(CH2)3Si(OCH3)3

Foreign Company's Trademark:

A-174(America Union Carbon)

Z-6030(Dowcorning)

KBM-503(ShinEtsu)

GF31(Wacker)

Features and Benefits

The methacryloxylsilane produced by silane KH-570.

· Significantly improves composite strengths when the composite is reinforced with fibreglass roving sized with a typical polyester-compatible formulation. These formulations normally incorporate silane coupling agents, film-forming resins, lubricants and antistatic agents.

· Enhances the strength performance, both initially and after wet-conditioning, of cured polyester resin composites filled with silica, glass, silicates and many metal oxides.

· Enhances the wet electrical properties of many mineral-filled composites, such as crosslinked polyethylene and polyvinyl chloride.

· May be copolymerized with vinyl acetate and acrylate or methacrylate monomers to prepare silylated polymers that are moisture-curable. These silylated polymer may be used in coatings, adhesives and sealants to provide superior adhesion and durability.

Typical Physical Properties

Determined on commercial material whose properties may vary within the specification limits.

_____________________________________________________

Physical Form Clear liquid

Colour, Pt-Co Max 30

Specific Gravity at 20°C, g/cm3 1.040 – 1.055

Refractive Index, nD 25°C 1.428 –1.432

Purity, % Min 98.0

Solubility

silane KH-570 is soluble in ethanol, methanol, isopropanol, acetone, benzene, toluene, and xylene. After hydrolysis it is soluble in water with adequate stirring if the pH is adjusted to 4.0. Hydrolysis releases methanol.

Application

1. Silane KH-570 has found its utility in the manufacturing of many intermediate goods such as: unsaturated polyester, ethylene-propylene diene copolymer, polystyrene, ABS, polyurethane, polybutadiene and polyethylene crosslinked by peroxide. For the finished goods like polyester reinforced material, Ethylene-propylene-non-conjugated diene cabel and so on. Modified by silane coupling agent, dihydrate gypsum gesso, can not only be used as filling of artificial marble to reinforce the bending strength of board but also greatly reduce the production cost of artificial marble.

2. Glass Fiber Soakage Agent

Glass fiber soakage agent is used in the treatment of glass fiber. It contains filmerformer, lubricant, anlistatig, silane coupling agent and water etc. The concentration of the silane coupling agent should be of 0.3%-0.6%.

3. Electrical wire and cable

When used in electrical wire and cable, silane KH-570 can greatly improve its mechanical performance and electrical performance in wet state. When applied in argil, silane KH-570 can dramatically better the consumption factor, inductance and capacitive reactance of the EPM (ethylene propylene monomer) and EPDM (Ethylene-Propylene-Diene Monomer) systems crossed linked by peroxide and filled with argil. Silane KH-570 results 2.5 times better than vinyl silane with the same dosage.

4. Filler Treatment

This silane can improve the mechanical strength of polyester composite materials made from filling white carbon black,glass, silicate and metal oxide in either dry or wet state, for instance, crosslinked polyethylene and polyvinyl chloride.

5. Adhesive and Coating

Silane KH-570 can be applied in acrylic resin and polyester adhesive in the purpose of improving its water resistance and adhesion stress with inorganic material, and also lowering its solidification value.

Package:

1. 25KGS/Plastic Drum

2. 200 KGS/Iron Drum

3. 1000KGS/IBC

Premiumsupplier

Premiumsupplier