- Product Details

Keywords

- silane coupling agent

- 1760-24-3

- A-1120,Z-6020, KBM-603,GF9

Quick Details

- ProName: Silane KH-792(A-1120)

- CasNo: 1760-24-3

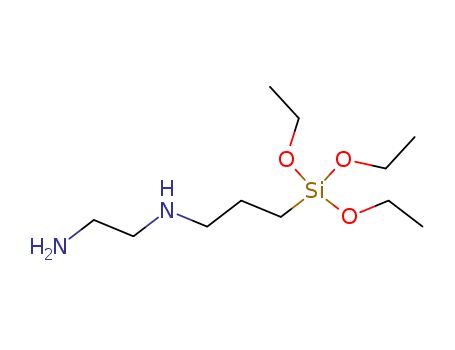

- Molecular Formula: NH2(CH2)2 NH(CH2)3Si(OCH3)3

- Appearance: Clear liquid

- Application: Coatings, Adhesives and Sealants

- DeliveryTime: 5 days

- PackAge: drum or IBC

- Port: Nanjing

- ProductionCapacity: 3000 Metric Ton/Year

- Purity: 97%min

- Storage: In the cool, dry place

- Transportation: by sea

- LimitNum: 5 Metric Ton

Superiority

silane KH-792 finds use as an :

· Adhesion promoter in polysulfide, polyvinyl chloride plastisol, silicone tow-part urethanes and epoxy adhesives and sealants

· Additive in phenolic and epoxy molding compounds

· Additive to latex coatings, adhesives and sealants

· Adhesion promoter in one-part silylated urethane adhesives and sealants based on organofuntional silane SPURSM Technology.

Details

Silane KH-792(A-1120)

Introduction

Chemical Name : N (beta-aminoethyl) gamma-aminopropyltrimethoxy-silane

CAS NO. : 1760-24-3

Molecular Formula:NH2(CH2)2 NH(CH2)3Si(OCH3)3

Foreign Company's Trademark:

A-1120(America Union Carbon)

Z-6020(Dowcorning)

KBM-603(ShinEtsu)

GF9(Wacker)

silane KH-792 finds use as an :

· Adhesion promoter in polysulfide, polyvinyl chloride plastisol, silicone tow-part urethanes and epoxy adhesives and sealants

· Additive in phenolic and epoxy molding compounds

· Additive to latex coatings, adhesives and sealants

· Adhesion promoter in one-part silylated urethane adhesives and sealants based on organofuntional silane SPURSM Technology.

Features and Benefits

Feature |

Benefit |

|

Polyamino functionality |

· Provides reactive site for amino-reactive resins. · Good wetting of substrates. |

|

Trifunctional silane |

· Excellent adhesion to inorganic substrates such as metal, glass, etc. · Superior adhesion to plastics when employed in SPUR Technology-based adhesives or sealants. |

Typical Physical Propertie

Physical Form Clear liquid

Color, Pt-Co max 25

Specific Gravity at 20oC 1.010 – 1.030

Refractive Index at 20oC 1.439 – 1.447

Purity, % 97.0 min

Applications

silane KH-792 may be used as an additive, eliminating the need for special primers in numerous bonding applications. Specific systems that demonstrate improved adhesion when silane KH-792 is used are:

RTV Silicones and Hybrid Silane-Crosslinked Sealants

Silane KH-792 addition to one- and two-part silicone-crosslinked sealants improves adhesion to a variety of substrates, including glass, steel, aluminum and concrete. This silane can dramatically enhance adhesion to a wide array of plastics when used in combination with SPURSM Technology for silylating urethane polymers. (For formulation and silylated prepolymer preparation information, please refer to Literature bulletin #112-026-30, “Silquest Organofunctional Silanes – Crosslinkers and Adhesion promoters for Urethane Adhesives and Sealants.”

Polysufide Sealants

When added to one- and two-part polysulfide sealants, silane KH-792 provides better adhesion to a variety of substrates, including glass, aluminum and steel. Silane KH-792 is typically used at a loading of 0.5 to 1.0 percent by weight to the sealant. It disperses well and produces cohesive failure in the sealant rather than adhesive failure of the bond between the sealant and the substrate.

Furthermore, the use of silane KH-792 can eliminate the need forprimers normally required to achieve adhesion to surfaces.

Plastisol Sealants

Adding silane KH-792(0.5 to 1.5 weight percent) as a replacement for polyaminoamide adhesion promoters in plastisol sealants improves bonding to metal substrates.

In addition to increased strength, the silane-modified plastisol sealant has better overall appearance than a system that uses polyaminoamide adhesion promoters. Silane KH-792-modified plastisol systems have a very light color, and the cured compound is bubble-free.

Additive in Phenolic and Epoxy Molding Compounds

Silane KH-792, as an additive in phenolic and epoxy molding compounds, reduces the water absorption of molded composites. This, in turn, leads to improved wet electrical properties, particularly at low frequencies. High-temperature strength properties are also improved.

Package:

1. 25KGS/Plastic Drum

2. 200 KGS/Iron Drum

3. 1000KGS/IBC

Premiumsupplier

Premiumsupplier